What is a 3 Dimensional Quality Control?

Engineering 3-Dimensional Quality Control evaluates industrially manufactured parts in detailed measures using 3D Quality Control Systems. Significantly during the pre-production stage of the manufacturing life cycle, this method can effectively optimize the final product.

What is Low-Volume Manufacturing?

Low-Volume Manufacturing or pre-mass production is a fast manufacturing technique for low-quantity production before the actual serial production begins. The printed objects can be used for tests and analyses to eliminate possible weak spots before significant investment.

What is Reverse Engineering?

Reverse Engineering represents different meanings for different industries. For manufacturing industries, it’s the process of CAD data generation for any given end product using digitalization systems. In other words, it’s the discovery of engineering secrets of any given end-product.

Rapid Tooling

Rapid Tooling is changing the manufacturing industry by revolutionising injection moulding. We are supporting the conventional production of plastic parts with selective laser sintering. In this case, the mould tool is 3D-printed. This opens new possibilities in design and minimises the product development cycle. Learn with us how to modernise your production and lower your lead times.

What is Rapid Prototyping?

Rapid Prototyping is about producing the parts with exact or close characteristics to prevent possible mistakes before a mass production process. At a much lower amount (like 1 to 100 units) than mass or pre-mass production, and based on the geometry of any given part, it’s possible to produce it in a few hours to a few days. You can manufacture your parts in basically five different manufacturing technologies.

Product Development

Product Development, or product management, is the conceptualization, design and marketing of your branded product through the whole product life-cycle. This management discipline aims to meet the changing market conditions and fully satisfy the customer’s needs. In the long term, this goal strives to maintain the competitive position of your company’s brand. Thus, the target group should be involved in the early product development process.

Topology Optimization

Topology optimization focuses on mass reduction while maintaining performance. The latest programs of this technology are calculating the best possible mechanical design. We can help you to optimize your part’s structure and durability. Learn how our engineers can shorten your lead times and increase your object’s performance.

CNC Machining

CNC machining is a production method using a computer numerically controlled system. It enables the high-speed production of parts with high precision, and eliminating the chance of human error provides more high and consistent quality. With our PLG Global manufacturing network, we can produce your designs with CNC machines anytime.

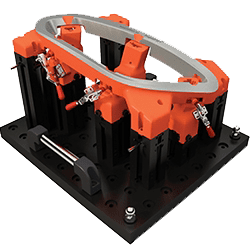

Jigs and Fixtures

Jigs and fixtures support any operation that requires a precise relationship in the position of a tool to a workpiece. Since complex applications need individual support, 3D-printing benefits from its design freedom. We produce customised 3D-printed jigs and fixtures for your project in the highest quality. Learn about it and become part of the Link to the Future.