Rapid Prototyping

What is Rapid Prototyping?

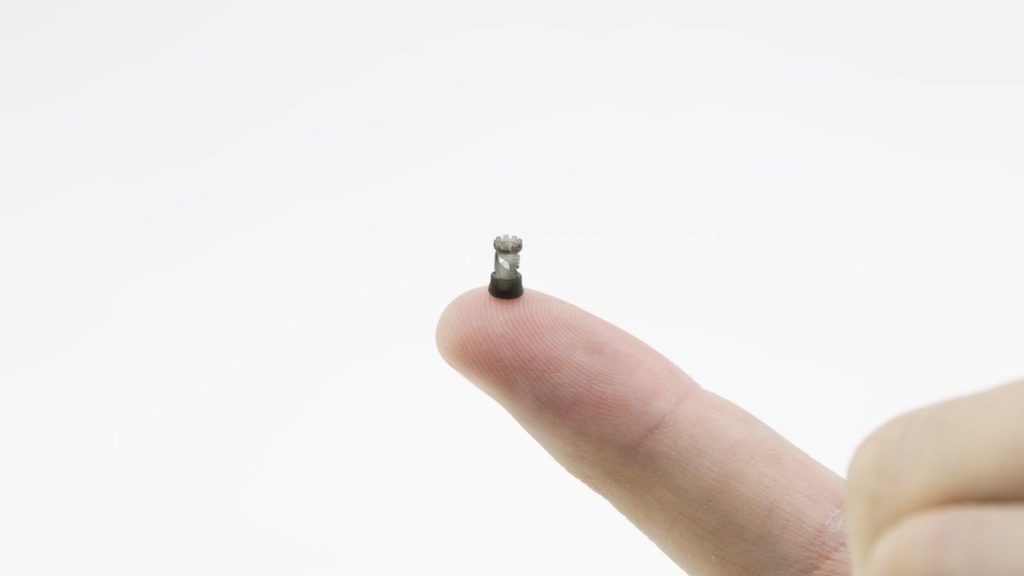

Rapid Prototyping is a fast manufacturing method that produces a model of a 3-dimensional computer-aided design utilizing 3D printing technologies. Our engineers process your CAD data to a physical object without detours with Nexa & Zortrax 3D printers. The relevant data interface in this process is usually STL, but our printers work with many other data formats. Please do not hesitate to contact us for further information. Our engineers will choose the most suitable manufacturing method for your desired object from our portfolio.

Rapid Prototyping Services in UK?

As your reliable partner PLG Global, we manufacture 3D printed objects with the SLA- / FDM- / DLS- Technology with Nexa & Zortrax printers in the United Kingdom. Our office is in Nottingham, so we proudly represent your 3D printing partner in the West Midlands region.

Rapid Prototyping Services Worldwide

Rapid Prototyping services are changing the manufacturing industry worldwide. Let us overcome the limitation of our in-house services by introducing the PLG Global Manufacturing Network. Our reliable partners are supporting our production capabilities with their service. Significantly our predecessor Poligon Engineering contributes to HP’s MJF Technology and other low-volume manufacturing technologies such as CNC-Machining, Silicone– / Aluminium– and Reaction Injection– Moulding. The PLG Global Manufacturing Network also opens your door to conventional production methods in other markets. Contact us directly to get the best prices for our 3D printing services.

Rapid Prototyping & 3D Printing

Rapid Prototyping can be fulfilled with additive manufacturing processes (commonly 3D Printing) and conventional processes such as subtractive (Milling, Grinding, Turning) or compressive (casting, compressive sintering, moulding). Consequently, Rapid Prototyping (=RP) is the general term for the manufacturing process, and 3D Printing is the utilized manufacturing method.

Rapid Prototyping Companies

As a rapid prototyping company in the United Kingdom, we offer five different manufacturing technologies locally. With the support of our PLG Global Manufacturing Network, we can provide you with all RP services with one partner. Please contact us, and our engineers will consult you about your production decision.

Rapid Prototyping & Stereolithography (SLA- or STL-Technology)

Rapid Prototyping with the SLA Technology is also known as Laser-Stereolithography (LS) or Photopolymerisation. As it implies, it is RP technology using photochemical processes by being exposed to a moving laser beam, and a thick photopolymer is cured in layers. The printing process starts with a movable build platform in a polymer resin reservoir. When the laser touches the resin, it polymerizes because the chemical monomers in the resin form cured polymers. After this process, the build platform moves one layer further and a coater deposits a new resin layer onto the previous layer. By repeating this process, the 3D printer creates the body of a 3-dimensional object. Then, the printed product has to be removed from the resin pool, and the supporting structure needs to be separated.

Theoretically, this is one of the most exact AM processes, and it can produce almost any product. Thus, it creates developing prototypes, medical models, computer hardware or other applications with excellent surface finish.

Rapid Prototyping & Fused Deposition Modeling (FDM-Technology)

Rapid Prototyping with the FDM Technology is also known as Fused Filament Fabrication (FFF) or Fused Layer Manufacturing (FLM). It is a 3D printing process with a continuous filament of a thermoplastic material. The extrusion head conveys striped plastic raw material, which is heated until it melts. The computer-controlled extrusion head forms the first layer of the component by pouring the material in drops on the build platform. The head moves in two dimensions while depositing a horizontal, and the build platform moves vertically to begin a new layer. When manufacturing overhangs, the printer forms a separate support structure that has to be removed from the part after completion.

Rapid Prototyping is one of the most widespread 3D printing processes, primarily found in affordable end-user printers. As a local re-seller of Nexa3D printers, we are experienced in setting up and using all machines in the UK.

Contact us for professional consulting.

Production & Selective Laser Sintering (SLS-Technology)

Rapid Prototyping with SLS Technology is known as Laser Sintering (LS). It is an additive manufacturing process that uses computer-aided manufacturing (CAM) software and a laser beam to powdered sinter material. The build chamber is heated below the fusion temperature of the material and filled with inert gas, creating the perfect atmosphere for the production process. Then, a coater spreads a polymer powder layer on the build platform. The layer scanner system exposes all relevant component cross-sections to light, thus sintering the powder. Afterwards, the platform moves by the thickness of a layer, and the process repeats itself.

After the creation of the object, it needs to be cooled down in a controlled manner to minimize any warping. Our engineers are experienced with all technologies and happy to help you select the most suitable production process.

Rapid Prototyping & Multi-Jet-Fusion (MJF-Technology)

The MJF Technology is also known as Multijet Modeling (MJM). It is an additive manufacturing process that applies tiny liquid droplets to a polymer powder layer, increasing or suppressing the powder’s heat absorption. An integrally working infrared source melts the material accordingly and creates the shape of the 3-dimensional object.

Like in SLS-Technology, UV light cures the raw monomers. The difference is the liquid droplets change the powder’s heat absorption. This opens the possibility of manufacturing sharp edges in combination with high-quality surface finishes. After creating a thin layer, the printer repeats the process by jetting new layers cured with UV light until the component is completely formed.

Thanks to the photopolymer, Polyjet can produce tiny features and refined textures. Thus, it is the perfect choice when details in the surface finish are most relevant. Contact us or our predecessor Poligon for any information about HP’s Multijet-Fusion.

Rapid Prototyping & Selective Laser Melting (SLM-Technology)

The SLM Technology is also known as Laser Metal Fusion (LMF-Techn.) or Laser Beam Melting (LBM-Techn.). It is a Rapid Prototyping Technology (for metal parts) similar to the SLS Technology. This additive manufacturing technique creates highly complex parts directly from 3D CAD data. The software on the computer slices the 3D data into thin 2D slices. Each of these sections will act as a blueprint for the SLM machine. The high-precision laser is conducted on metal powder particles to create thin horizontal 2D metal layers. For overhangs, a removable metallic support structure is required. This process is reserved for materials such as Titanium, steel, cobalt-chrome, Inconel and aluminium. Various functional metals are available to print components, from prototypes to low-volume production series of up to 20000 units. SLM is the perfect choice for durable and functional metal prototypes.

Rapid Prototyping Applications

Concept modelling applications

Rapid Prototyping processes a solid model of a designed project within a few hours to hold the design in your hand. Thus, it allows one to analyze the concept model and start marketing efforts before mass production begins.

Functionality Applications

Through Rapid Prototyping, you can test the design’s functional properties. The prototype consisting of equal material can be checked mechanically with a crash or pull tests and chemically. Testing before the actual mass production minimizes your company’s risk of failure.

Production Supportive Element Applications

Rapid Prototyping generally produces supporting parts for assembly processes, and it opens the possibility of producing individualized objects. Thus, we can manufacture your parts faster and more economically than conventional.

End-User Part Applications

Rapid Prototyping helps you create customised custom order productions in lower units for a reasonable price. This application allows your company to produce fast and without moulding investment.

Advantages of Rapid Prototyping

- Rapid Prototyping saves time & money.

- Explore projects quickly on a physical level.

- Communicate projects effectively with clients & customers.

- 3D printing opens the possibility of producing complex parts at once.

- Prevent mistakes in design and functionality.

Important Factors of Rapid Prototyping

- In some cases, costs per unit might be higher than using conventional methods.

- Some applications cannot be realized with the original material.

- RP might reveal hidden problems before the serial production.