Rapid Tooling

What is Rapid Tooling?

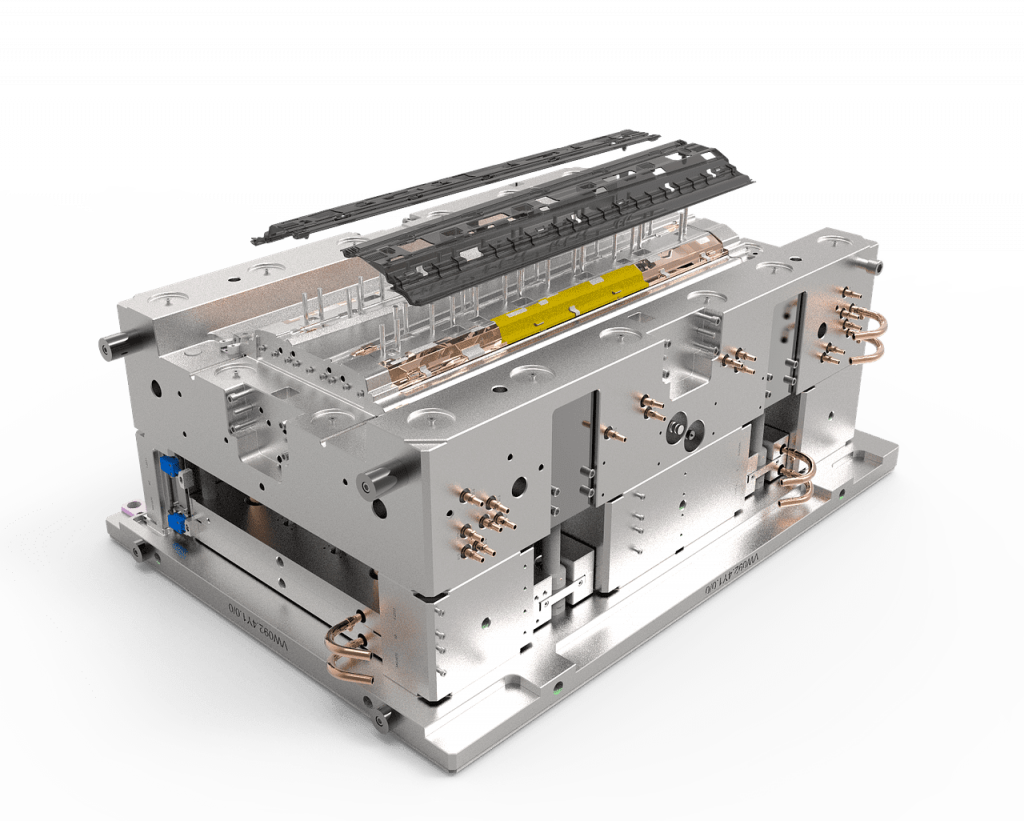

Rapid Tooling is a concept that is changing the manufacturing industry. For understanding, we have to keep in mind that injection moulding is the status quo of producing plastic parts in high volume. For that, the mould tool for production can be expensive and risky during the development stage of your product. This issue can be solved by using SLS (selective laser sintering), a type of 3D printing. This process opens the possibility of producing the moulding tool much faster and cheaper. Contacting our engineers can save you and your company a lot of money because they create the mould tool faster than conventional production methods.

How to Process Rapid Prototype Tooling?

As you can see from our engineering overview, SLS is a way of 3D printing where a laser melts the metal powder, and the molten metal creates a 3-dimensional part. In Rapid Tooling, this part is used as the prototype for recreating this as plastic parts. Rapid Tooling can reduce the time required to produce a mould tool by cutting the prep work to the least. Consequently, this process can save you and your company precious time and money.

Solutions

Rapid Tooling as technology eases injection moulding.

Advantages

- Minimizing the costs per unit in injection moulding techniques

- Cutting the processing time to a minimum

- Increasing flexibility during the development stage of your product

- Reducing prep work of the master model

Critical Factors to Consider in Rapid Tooling

- Executing engineers might get confused by the complexity of the process

- When engineers are focusing on an aspect of the process, they might distract themselves from doing a complete product analysis

- Contact us to work with some of the most experienced engineers in the field

- The tool making process stays to be a time-consuming step in the product development cycle