Analysis & Simulation

What is Dynamic Analysis?

Dynamic stress can be obtained from the experiment (sensor or assembly sensor on a physical component) or simulation. Before calculating the correct dynamic pressure, a representative load history should be created using simulation, including inertia and external forces (e.g. joint reaction forces and torques). Multi-body dynamic analysis methods (discussed in Chapter 3), typically used for dynamic motion analysis, can be used for dynamic load analysis of mechanical systems. All bodies of the dynamic model are generally assumed to be rigid. The rigid body assumption for a vehicle’s suspension components often yields reasonably accurate analysis results to support structural design for durability.

What is Finite Element Analysis?

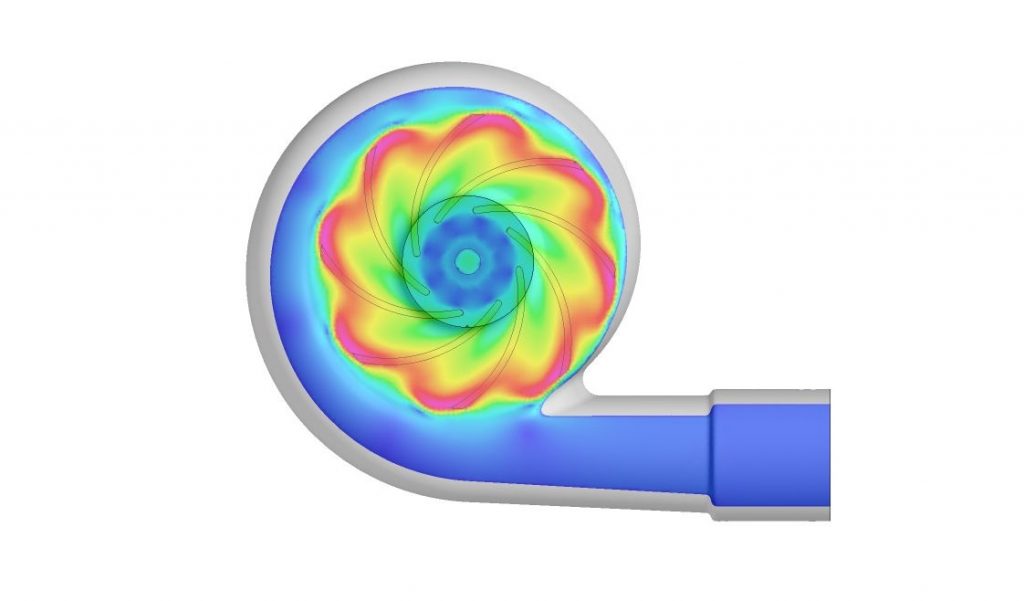

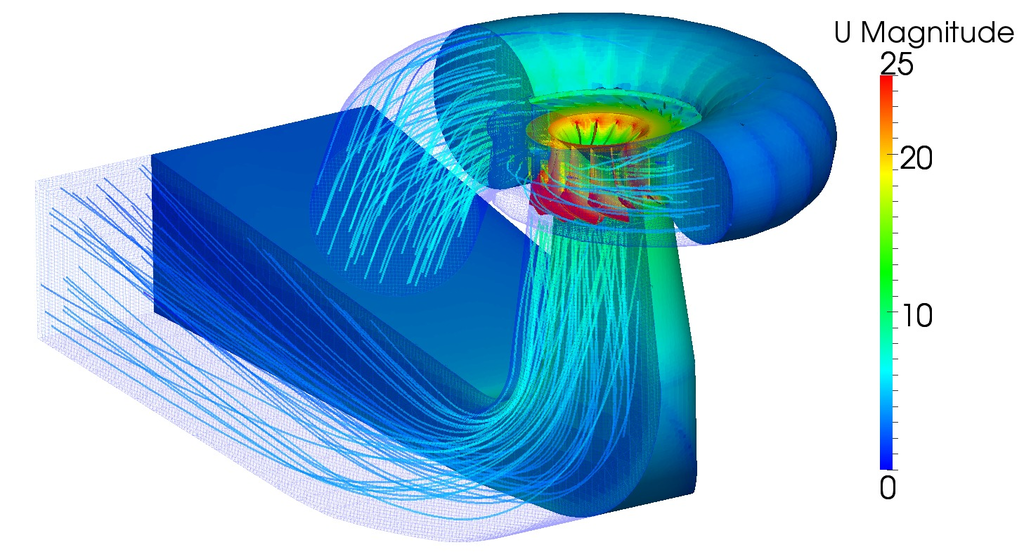

Finite element analysis (FEA) measures and concludes how a product or a system reacts to physical conditions such as force, impact, vibration, shock wave, heat resistance, and fluid flow under current living conditions. Finite element analysis shows whether the product works as broken, worn out or designed. This method is one of the key processes in the product development process. FEA divides a real object into several (hundreds of thousands) finite elements, such as small cubes and prisms. This method examines the state of each mesh structure through mathematical equations under physical conditions. A top mathematical equation looks at all of these mesh structures holistically. Finite element analysis helps predict the behaviour of products affected by many physical influences, including:

- Mechanical Stress

- Mechanical Vibration

- Fatigue

- Movement

- Heat Transfer

- Liquid Flow

- Electrostatic

- Plastic Injection Moulding

Advantages of Analysis & Simulation

- It is a digital test method, and the parts can be examined in a virtual computer environment before physically producing.

- Since the possible problems are displayed in the computer environment, the arrangements are revised in design and essential steps are taken to smooth the procedure.

- Structural behaviour and fault visualization are performed under various loading conditions.

- Insight information (Weight, Power, Cost) for critical design parameters are acquired.

- Faster and cheaper design cycle

- Weight reduction, topology optimization, and metal substitution material changes can be made with finite element method with faster, more effective and more economical methods.